3D Printing: Solving Everyday Problems and an e-commerce Brand

I think 3D printing is an under appreciated magical technology that enables anyone with a modicum of technology skills to solve vexing every day problems themselves – the annoying problems that plague us all and lack a solution we can purchase from the market.

I think 3D printing is an under appreciated magical technology that enables anyone with a modicum of technology skills to solve vexing every day problems themselves – the annoying problems that plague us all and lack a solution we can purchase from the market.

I've been in the 3D printing space since 2014 when I purchased a MakerGear M2 – built in Ohio, US. Over 10+ years I've learned so much about different formulations of plastics: PLA, ABS, PETG, Nylon, PVA, HIPS, Carbon-Infused (CF) variants, Glass-Infused (GF) variants and, more recently, PCTG. After the MakerGear M2, I upgraded to the MakerGear M3-ID and, more recently, the Bambu Labs X1C – I've seen this industry mature and enable greater sophistication for low-volume plastic manufacturing. For a brief moment around 2015 3D printing became a technology fad – it even got its own well-received documentary Print the Legend, which I highly recommend.

The Phomemo M220

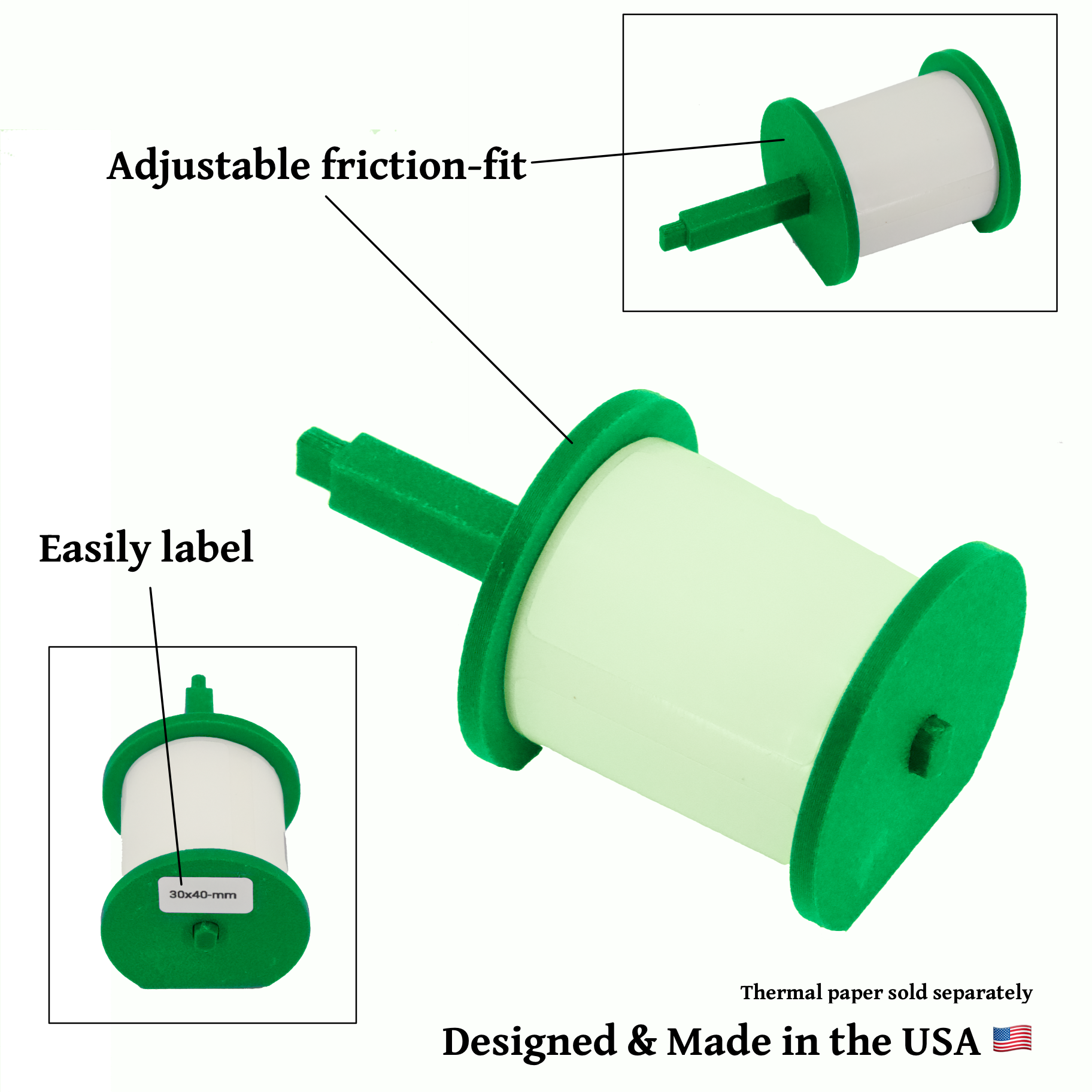

I own a Phomemo M220 thermal printer that I use to label items around the house. Inside the thermal printer there is a simple black plastic device that enables you to load thermal paper rolls of varying dimensions – it has a sliding mechanism to accommodate differing lengths. You can see the mechanism on the Phomemo M220 website:

It is impossible to purchase a spare plastic mechanism anywhere – you cannot buy it from Phomemo and its not found on Amazon.com either (more on that later). I needed spares of this mechanism to enable me to have "ready to go" thermal paper rolls I could "quick swap" between as needed. And the mechanism could be improved by enabling a "flat-packed" feature inspired by IKEA – it would take less space and store far more easily than the current design.

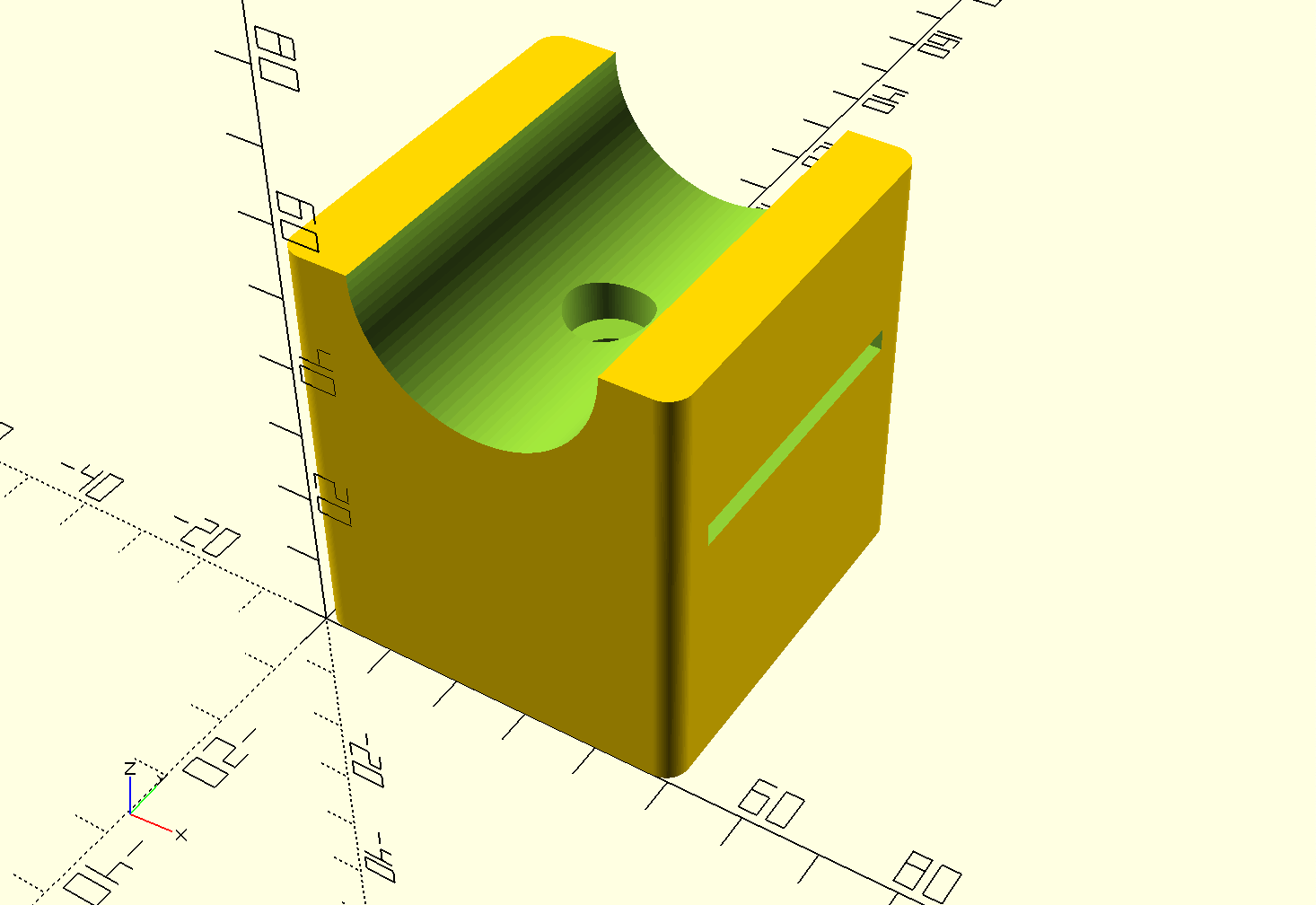

So, I designed my own mechanism for the Phomemo M220 that I refined iteratively and printed myself on my 3D printer. I chose PCTG because of this plastic's robustness, flexibility, and "just right" friction. The result is a drop-in replacement for the mechanism that comes with the Phomemo M220.

The improved Phomemo M220 thermal paper plastic roll holder

The Yakima Bike Rack

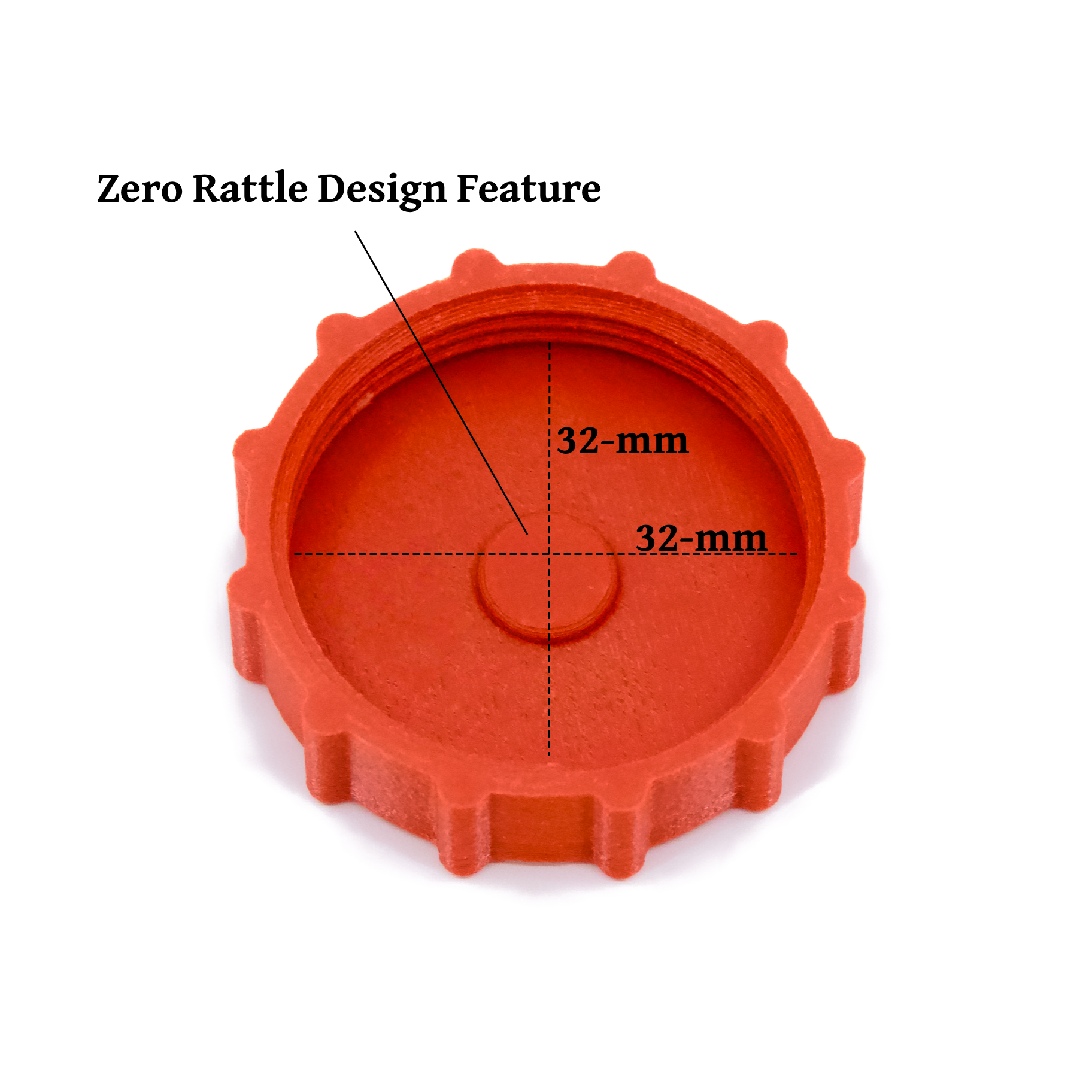

I own a Yakima bike rack I use when taking my bicycle around the beautiful PNW. The bike rack is very robust and weighs a heft 32-lb. Given its shape, its awkward to store – it spent a non-trivial amount of time laying on the floor of my garage where it was an ever present tripping hazard and was taking valuable real estate.

Recently while doing my 2025 Spring cleaning I noticed that this "dead space" corner of my garage was tempting for use as a storage space for the bike rack. The problem? How do I keep the bike rack from falling over and damaging a vehicle, hurting someone or pinning the garage door from the inside?

To my engineering mind, the answer was obvious: a non-load bearing bracket that locks the bike rack upright in place. But you cannot buy such a bracket. So I solved this "every day problem" using 3D printing. Within 30-min I had a design that was printed in about 45-min in PLA for prototyping. Surprisingly the very first prototype worked perfectly using velcro straps to enable quick attach/detach; the dimensions or design needed no changes.

The production version of the bracket was printed using PETG-CF, which is a carbon infused variant of PETG. I chose this plastic because of its robustness, flexibility (i.e., it fails gracefully) and professional looking finish (i.e., it looks like something you purchased from an injection molder).

Production non-load bearing bracket

All of the items I design and print are inspired by every day problems I come across during my normal day. I use Python to code the widgets using SolidPython2 to convert between Python and OpenSCAD. Since I am a physicist and mathematician by education, using basic geometric shapes and algebraic transformations as the fundamentals for designing objects appeals to me; as opposed to the CAD software approach others take whereby they draw their designs.

Raspberry Pis

A few years ago I wanted to learn more about Kubernetes so I built my own 4-node cluster using Raspberry Pi 4Bs (RPi4B) and Power Over Ethernet (POE) hats. Instead of buying one of the many expensive and inflexible RPi cases, I designed my own modular case that can be mix and matched to handle different RPi hardware variants.

Later on I took the same idea to design a modular case for the Raspberry Pi 2W – the mini version of their single board computers. In the example below, you see one version that accommodates GPIO pins and another that does not have any.

AirTags

I love the Apple AirTags and have attached them to my luggage, backpacks, bicycles, and much more. At first I would throw the AirTags into the zippered mesh of my luggage but found that inelegant. Then I realized that all luggage includes a zipper on at least one internal side that provides access to the inner shell of the luggage. Now all I needed was some sort of device to securely attach the AirTag under the liner on the upper inside of the luggage. You know where I am going with this...

An AirShell for an AirTag

I am NOT Special

As much as I would like to think I am a special snowflake, the reality is all the every day problems I see are not unique to me. If these problems challenge me and need a solution, its likely they affect many more people. Given my entrepreneurial mindset, my love of problem solving, and my knowledge of e-commerce this led to my second co-owned e-commerce brand 3nterprise where others can purchase the solutions I (and others) design to solve the same problems that bother me.

What makes 3nterprise special is that every product is a solution to what I call an "orphaned problem" – that is, a problem that we encounter but has no ideal solution you can purchase in the marketplace. In 3nterprise I merge three defining skillsets: 1) technology; 2) e-commerce; and 3) entrepreneurial mindset with my long-built expertise in 3D printing, software coding, and mathematical formal education.

3nterprise products to make your every day problem go away

If you want to learn more or chat about 3D printing, 3nteprise or anything else, drop me an email or comment below. If you come across an annoying problem that could use a solution, also contact me because I am always eager to design and release new solutions.